Screw taps and thread cutting dies

in real BAER quality

Screw taps and thread cutting dies in real BAER quality

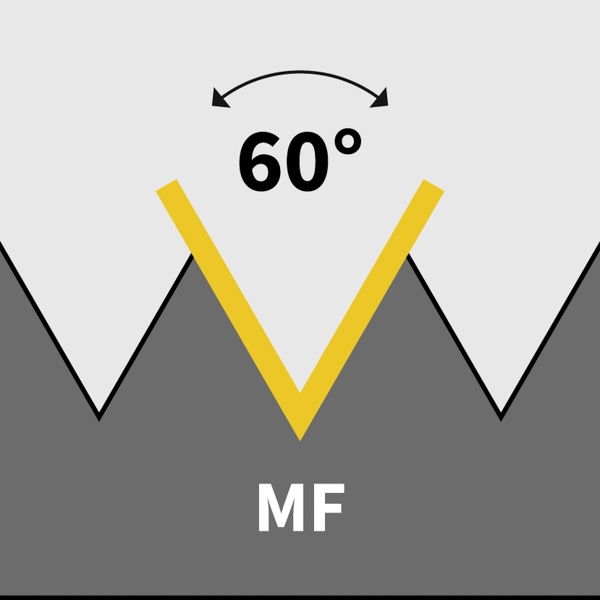

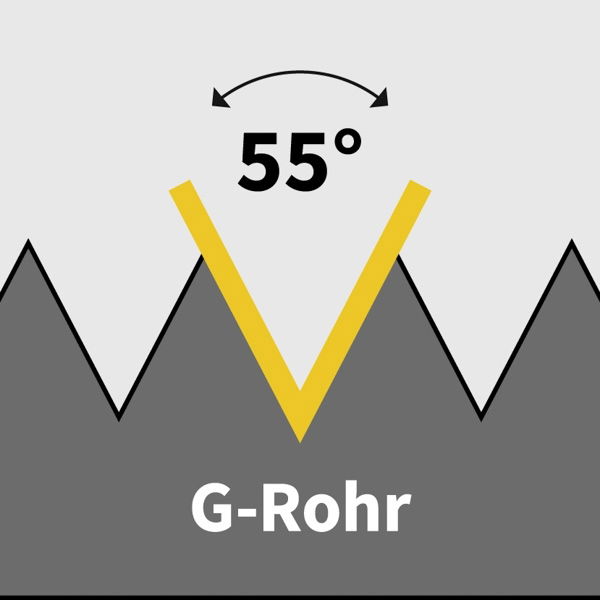

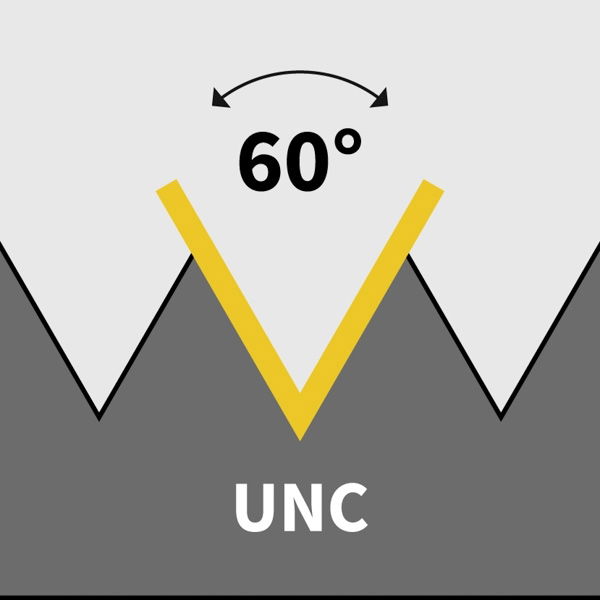

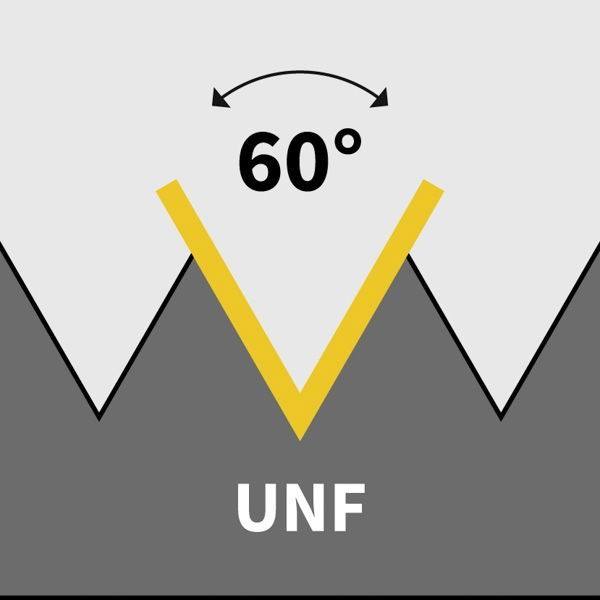

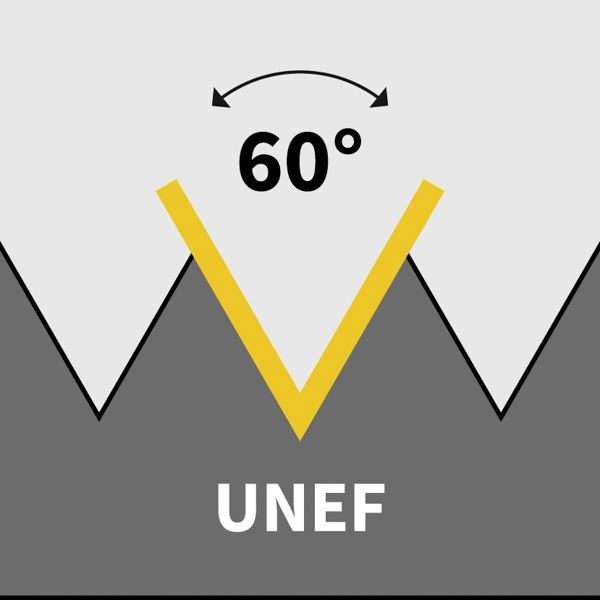

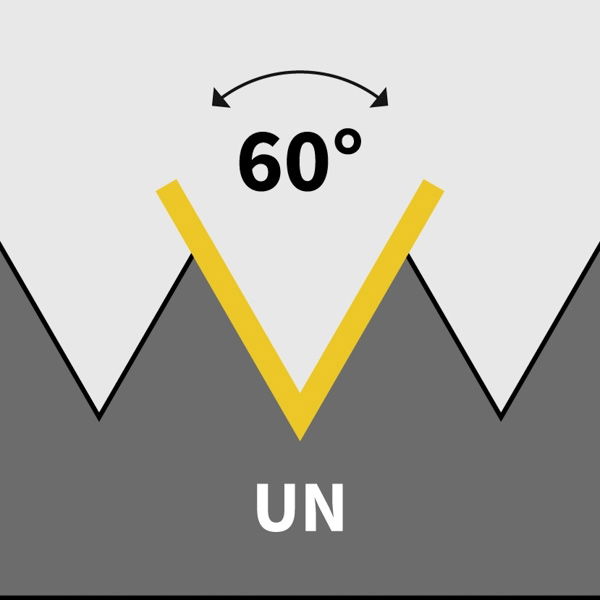

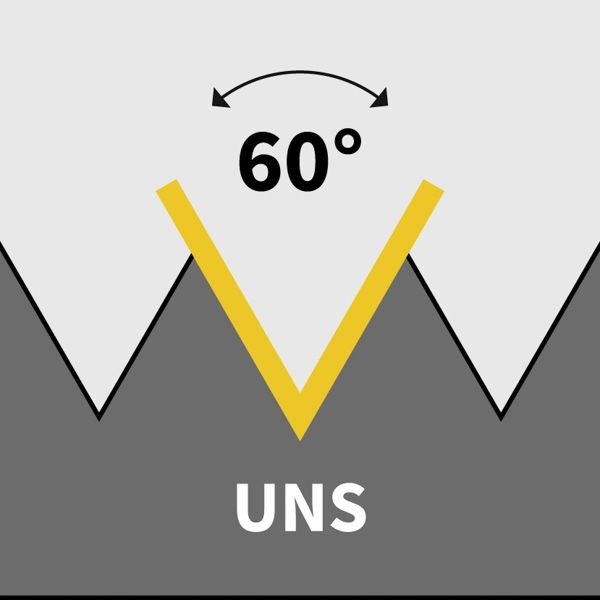

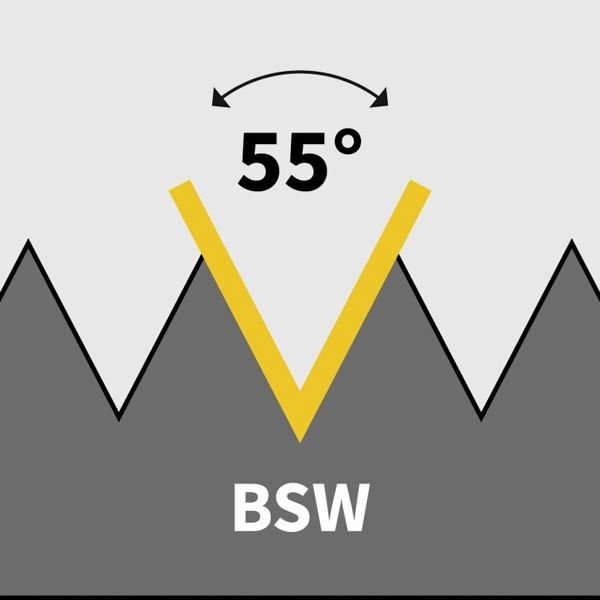

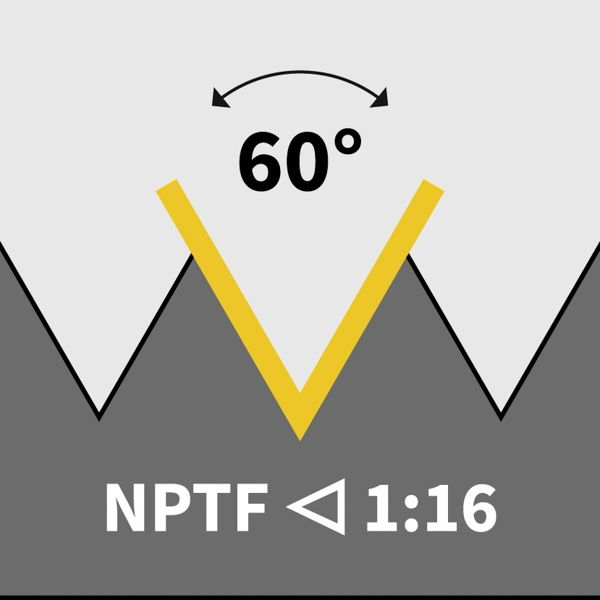

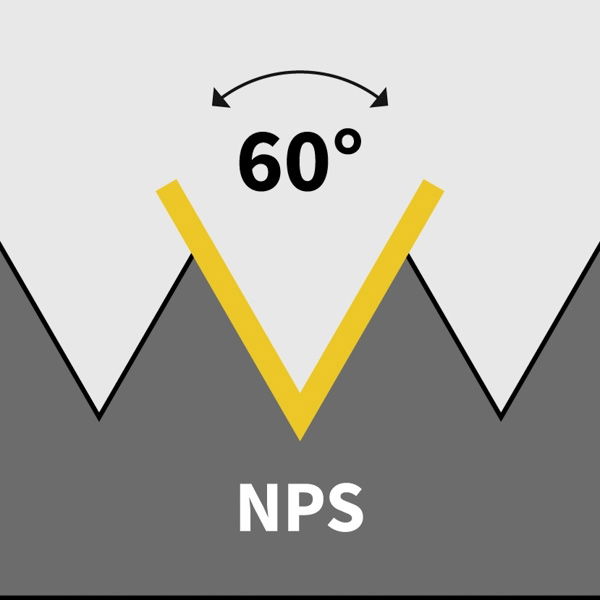

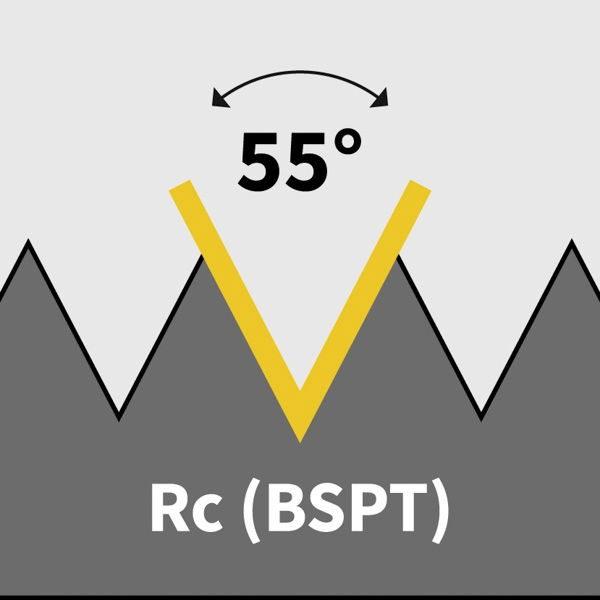

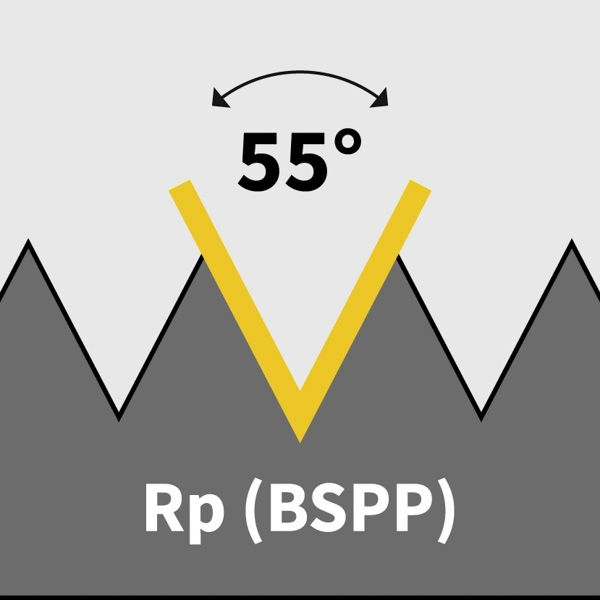

Thread standards

Threading tools for cutting threads - screw taps and cutting dies

BAER is your reliable supplier for high quality and durable screw taps. We offer machine as well as hand taps and thread cutting dies to cover your needs. Our wide selection of tools guarantees the perfect form of internal and external threads. You can rely on our top quality and excellent value for money. For 40 years, we have been your reliable partner in thread machining as an independent family-owned company. Our experience and excellent service have enabled us to successfully master any challenge. Trust us if you are looking for high-quality tools and first-class advice. Buy taps and dies directly here in our online shop and convince yourself of our service promise and quality.

Topseller

Screw taps and thread cutting dies according thread standards

Accessories

Screw taps and thread cutting dies

convince with BAER quality

A professional threading tool can be recognised by its precise grinding pattern and burr-free cutting edges. This is because temperature and friction are reduced, which leads to improved chip removal. You can rely on this with the taps and taps from BAER Tools.

We manufacture tools for professionals and act like professionals ourselves. Because we always maintain a high-quality industrial quality. Our high-precision manufacturing ensures long tool life and the best tool quality you can imagine. To give you optimum security, our quality management is ISO 9001 certified. If you are looking for strong tools with high standards, you have come to the right place.

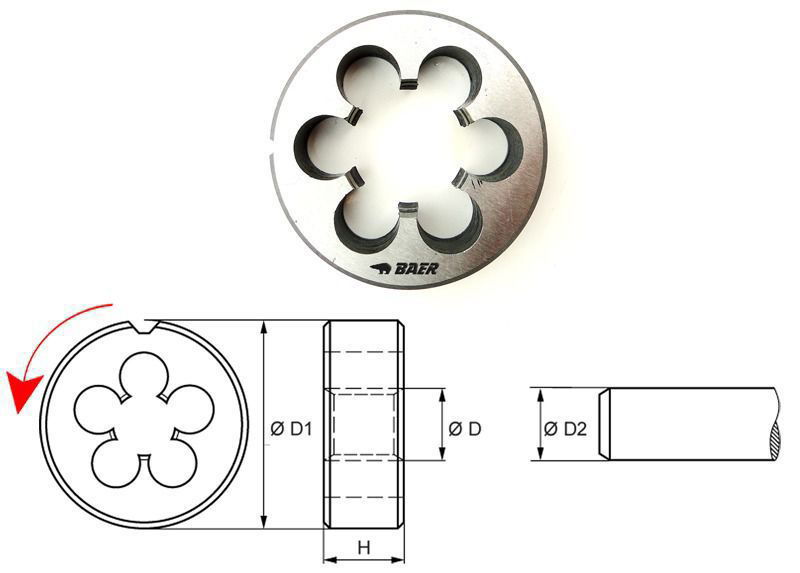

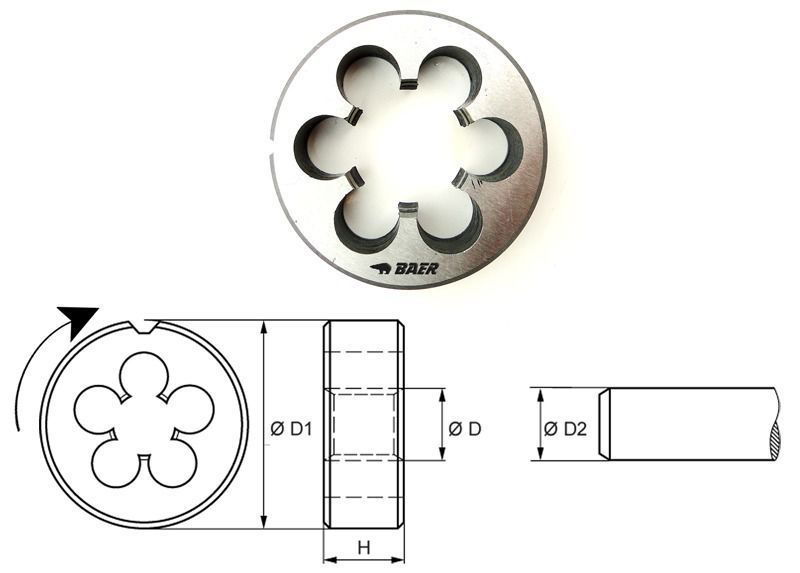

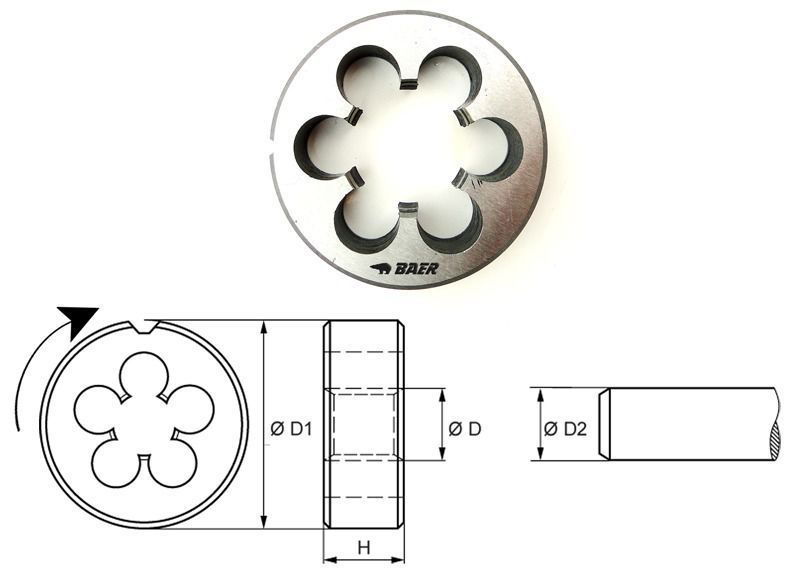

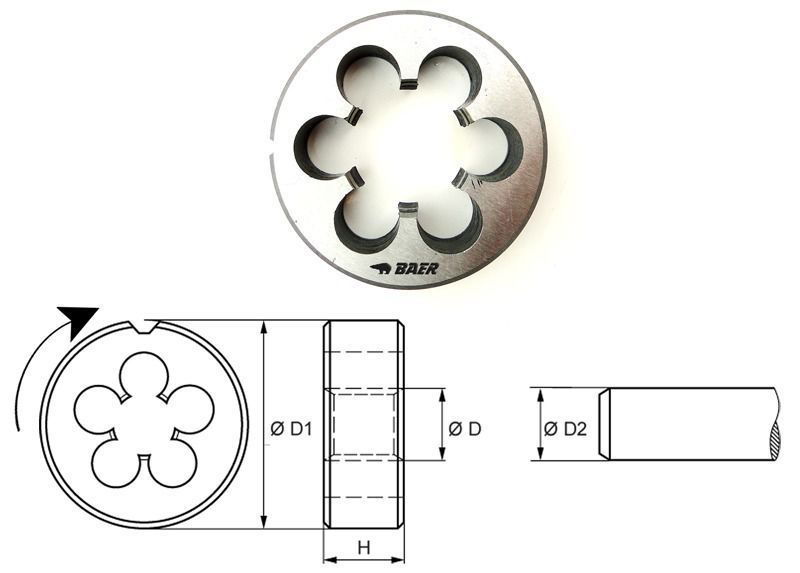

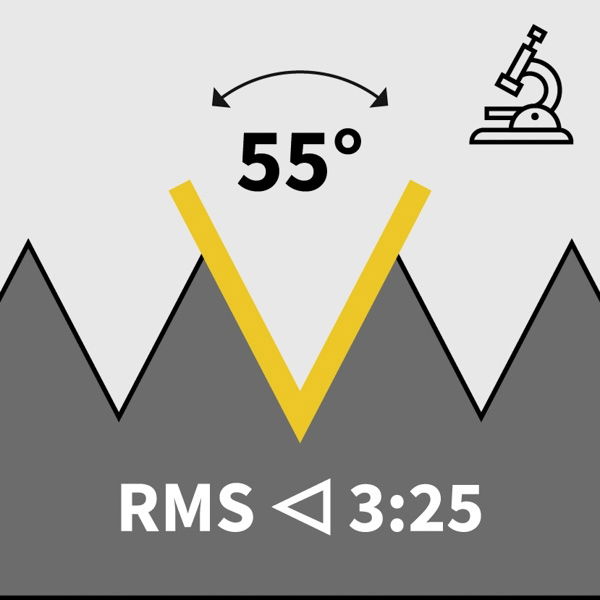

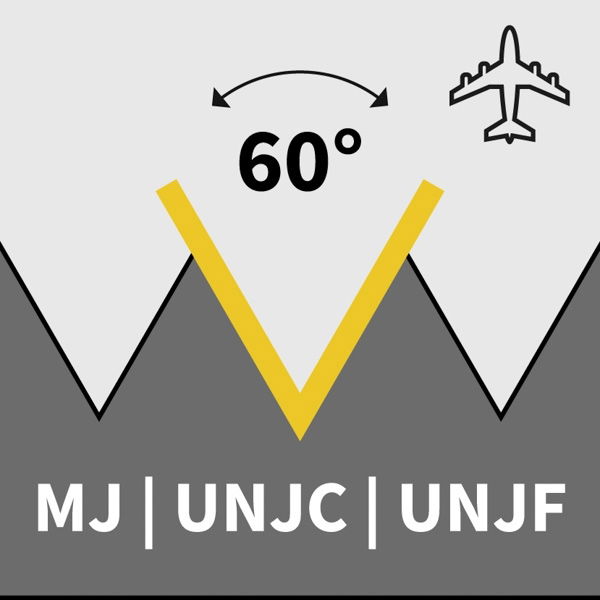

Thread cutting dies for precise external threads

Taps are particularly versatile and powerful tools. They are needed when it comes to producing precise external threads that are cut on bolts. At BAER you have a large selection for different angles. They are suitable for different materials and can be operated either mechanically or manually. Our BAER taps are suitable for cutting bolts and screws - and that in many different thread types and thread standards.

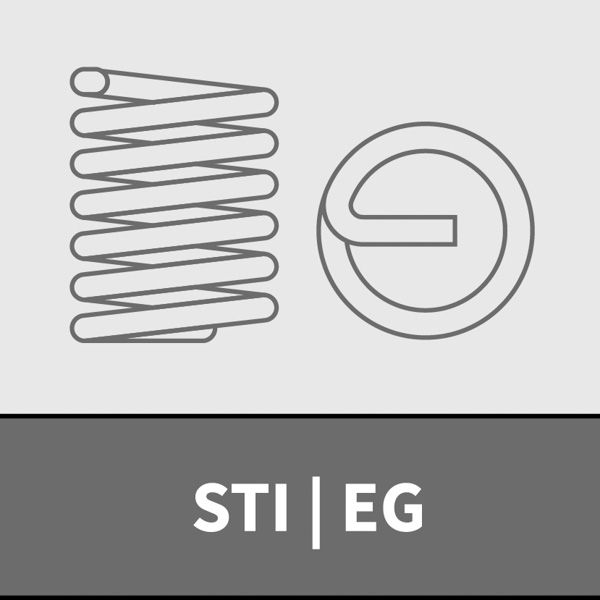

This is what BAER thread cutting dies look like

Our thread cutting dies are cylindrical and have three or more cutting edges. The holes on cutting die or flutes on screw taps between the cutting edges pick up chips, roll them and carry them away. The material is high-speed steel.

When using a thread cutting tool, it is important that it is kept straight all the time. It should also be secured with screws during use so that it does not twist. It should also be sufficiently lubricated before use.

How do I choose the right threading tool?

While round thread cutting dies are best used together with die stocks or machines, hexagon die nuts are optimal for spanners or hexagon nuts.

Among the round threading tools there are those for normal use or those that are suitable for special materials. For example, if you want to cut stainless steel, you need a particularly powerful threading tool. A thread cutting die for brass also needs to be carefully selected. Undersize thread cutting dies are particularly suitable if the materials are to be treated further after cutting. For particularly special cases, we will also be happy to manufacture a suitable thread cutting die for you. Please contact us and we will design your individual thread cutting tool together.

Advantages of our threading tools

In addition to their outstanding quality, threading tools from BAER have many other convincing advantages. They can also be used in tight spaces and require little torque due to their particularly sharp cutting edges. They are versatile, as they are suitable for simple tapping attachments up to multi-spindle machines. Thread cutting dies can also be used from both sides, depending on the design.

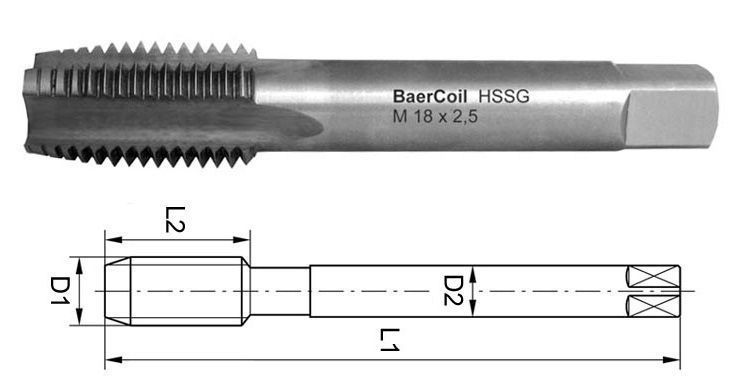

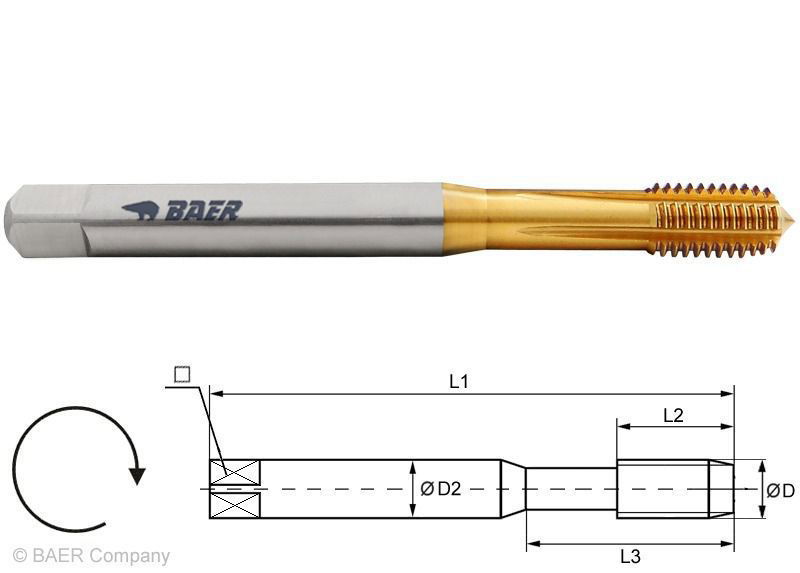

Screw taps for perfect internal threads

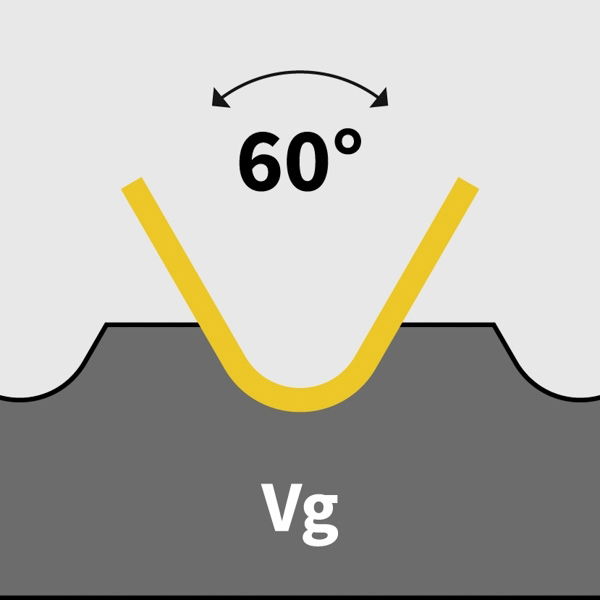

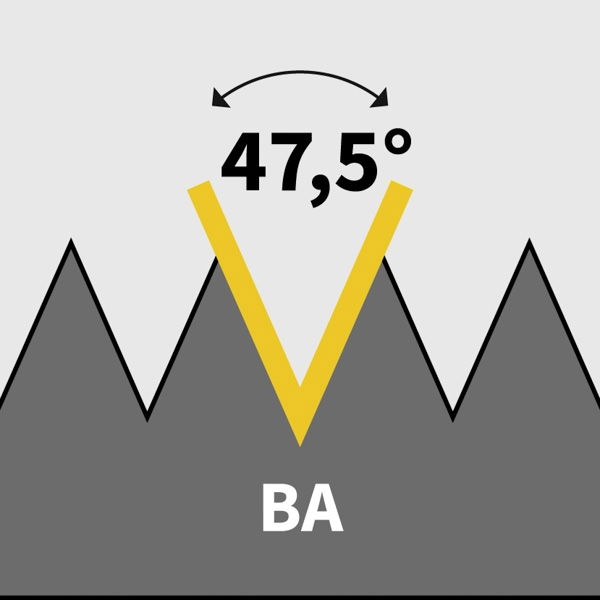

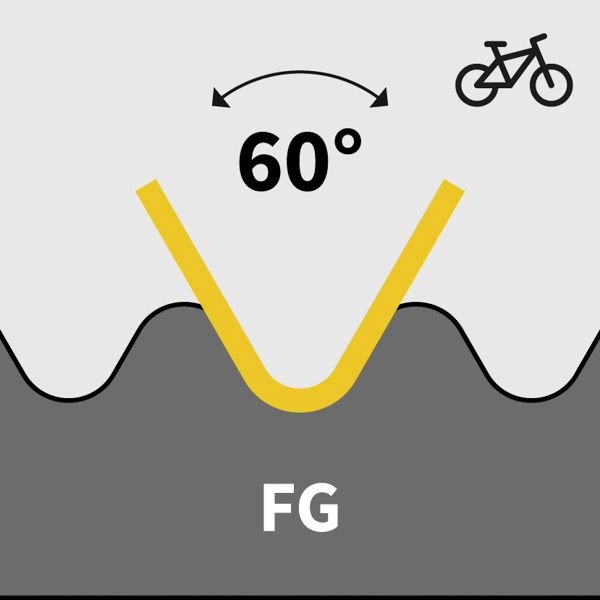

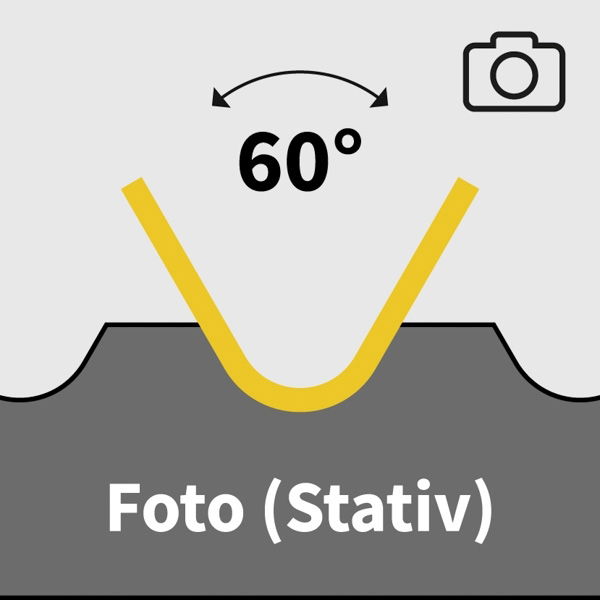

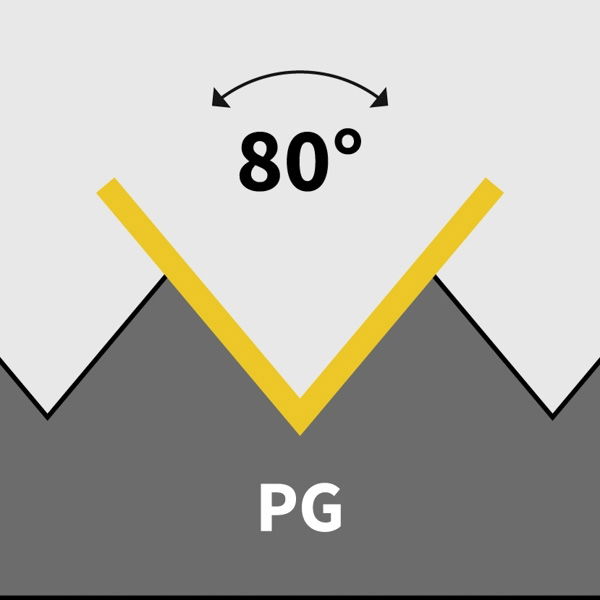

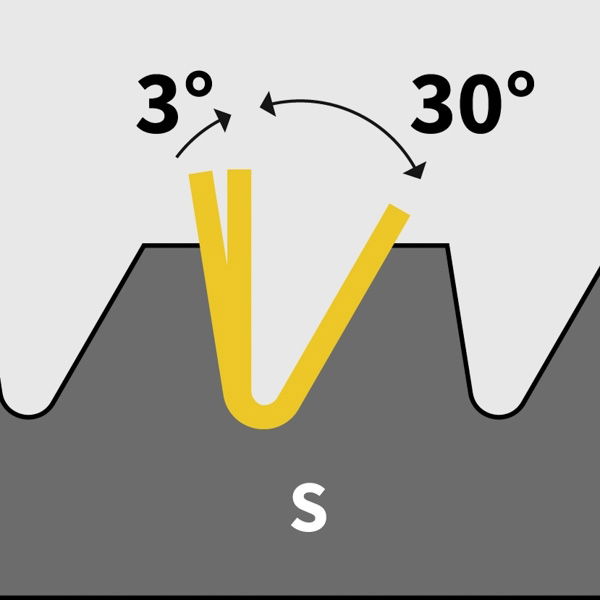

Screw taps from BAER are suitable for producing perfect internal threads in bores, holes or pipes. But how do you choose the right screw tap? First ask yourself whether you want to operate the screw tap manually or mechanically. Hand taps and machine taps, for example, are suitable for manual use. For machine use, a machine tap must be used. Furthermore, clamping angles, base materials and surface treatments must be considered when choosing a threading tool.

If you are looking for high-quality and versatile screw taps, be sure to also check out BaerCoil. Here you will find short machine taps for wire thread inserts, practical combined taps or the PRO machine tap for wire thread inserts.

Taps and dies in high quality boxes

When you buy screw taps or thread cutting dies from BAER, they are supplied in a high quality box. The boxes for our tools are either made of plastic, wood or sheet metal. This way you have a practical storage option right away and do not misplace your screw tap or thread cutting die. Concentrate on the essentials while we take care of the optimal packaging of your threading tools.

Screw taps and thread cutting dies - accessories

High-quality screw taps and thread cutting dies are just as important for producing internal and external threads as the right accessories. That is why our online shop provides you with everything you need.

With lubricants, you can keep your taps and drills in good condition and extend their service life. This ensures that the quality remains impeccable even after prolonged use.

For repairing damaged threads, you will find complete repair kits and drill sets at BaerFix and BaerCoil . Here you have everything you need right at hand in one case. You can also find thread inserts and other assembly tools here.

Order screw taps and thread cutting dies online

When you buy screw taps or thread cutting dies from us, you benefit from our numerous shopping advantages. Among them, for example, our large selection of payment options. Pay by Paypal, credit card, invoice, direct debit, VISA or Mastercard or Amazon Pay - whatever suits you best. We also deliver quickly and reliably to many different countries. If you have a question or need advice, please feel free to contact us.

BAER will be happy to assist you with expertise and professional advice.

FAQ

Thread cutter (cutting threads)

Taps are used to create new internal and external threads on screws, nuts, bolts and other components or to repair existing threads. Taps come in many designs for various materials and thread standards and sizes.

Actuating tools such as tap wrenches, tool ratchets or die holders are used to turn dies and taps during manual use and to cut threads precisely. They offer improved power transmission, protect the hands and enable efficient work when producing internal and external threads.

Advantages: precise thread production, increased safety, efficient working

They are indispensable tools for DIY enthusiasts and professionals.

Our comprehensive range for professional threading work includes:

- Tapping operating tools: High-quality hand tools for precise manual operation of taps. Ideal for metalworking and mechanical engineering.

- Lubricants: Specially developed cutting oils and cutting pastes to optimize tapping performance and minimize tool wear. Indispensable for efficient thread cutting.

- Thread gauges for quality control: Precise measuring instruments for accurately checking thread quality and accuracy. Essential for quality assurance in mechanical engineering.

- Countersinks for drill holes: Professional tools for precise countersinking and clean deburring of bores. Perfect for the preparation of threaded holes.

- Thread restorer sets: Effective solutions for recutting and thoroughly cleaning damaged threads. Indispensable for repair and maintenance work. With this comprehensive thread cutting range, we cover all important aspects of thread machining. We offer you the necessary precision tools for efficient and high-quality threading work in industry, trade and the DIY sector.

A thread restorer from BAER is a specialized tool for repairing damaged threads. It is used to recut and smooth threads without enlarging them. Ideal for repairs in workshops and industrial applications as it saves time and money. The thread restorer is versatile and suitable for various materials such as steel, aluminum and plastic.

Lubricants are indispensable for efficient and precise thread cutting. They are used:

- To reduce friction: Lubricants minimize friction between the tool and the workpiece, which significantly improves cutting performance.

- For heat dissipation: They help to dissipate the heat generated during the cutting process and thus prevent overheating.

- For tool protection: Through reduced friction and heat, the service life of your threading tools is significantly extended.

- For better surface quality: Lubricants contribute to a smoother thread surface.

- For all threading work: Recommended for manual and machine threading operations in various materials. High-quality thread cutting oils or pastes should be used in every cutting process to achieve optimum results and protect your tools.

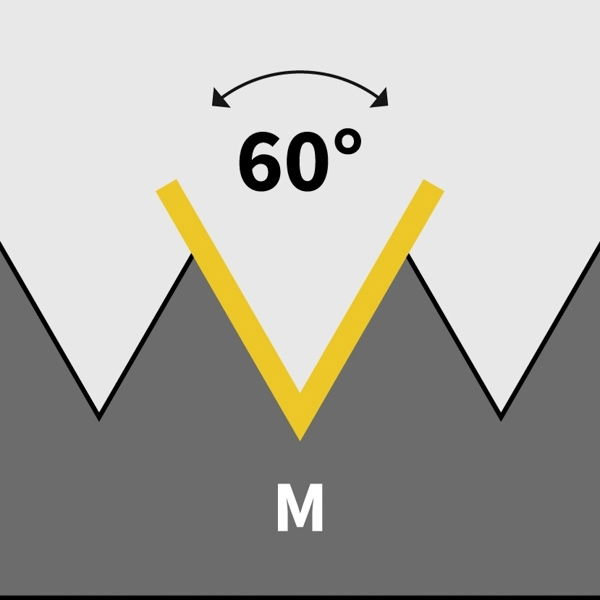

Metric taps are suitable for a wide range of materials and are versatile. They can precisely machine metals such as steel, stainless steel, aluminum, brass and copper. They are also ideal for machining plastics and other soft materials. It is important to select the right tap for the respective material in order to achieve optimum results and extend the service life of the tool. Also pay attention to correct lubrication and cooling, especially with harder materials such as stainless steel.

Antwort: Kurz gesagt: Im Alltag werden beide Begriffe oft synonym verwendet, doch fachlich gibt es einen entscheidenden Unterschied.

Gewindebohrer: Dies ist der korrekte Fachbegriff für Werkzeuge, mit denen Sie Innengewinde (also in ein Loch hinein) fertigen. Ein Gewindebohrer schneidet – bzw. bei speziellen Ausführungen formt – das Gewinde in ein zuvor erstelltes Kernloch. Wenn Sie also eine Schraube in ein Bauteil eindrehen möchten, benötigen Sie einen Gewindebohrer.

Gewindeschneider: Dieser Begriff wird umgangssprachlich häufig als Sammelbegriff für Werkzeuge verwendet, mit denen Gewinde hergestellt werden. Fachlich korrekt unterscheidet man jedoch zwischen Gewindebohrern für Innengewinde und Schneideisen für Außengewinde (z. B. für Bolzen oder Rohre). „Gewindeschneider“ ist somit kein normgerechter Werkzeugbegriff, sondern eine gebräuchliche Bezeichnung.

Warum ist das wichtig? Auch wenn viele Heimwerker nach einem „Gewindeschneider-Set“ suchen, meinen sie meist ein Set aus Gewindebohrern (für Innengewinde) und Schneideisen (für Außengewinde). Bei BAER Tools legen wir Wert auf Präzision: Wenn Sie bei uns nach einem Gewindebohrer suchen, erhalten Sie ein spezialisiertes Werkzeug für maßhaltige und saubere Innengewinde – egal ob für die Handanwendung oder für den Einsatz in der Maschine.

Taps (internal thread)

Taps are tools that cut internal threads in materials such as metal or plastic. They work by removing material with sharp cutting edges and thereby creating precise threads. BAER offers a wide range of high-quality taps for a wide range of applications and materials.

- Hand tap: Ideal for manual applications, repairs and hobby work. They are often offered in sets (pre-cutter, middle cutter, finished cutter).

- Machine tap: Designed for use in stationary machines and industrial applications. They enable fast and precise work.

- Bit tap: Perfect for use with cordless screwdrivers, ideal for flexible uses.

- Combination machine tap: Combine drilling and tapping in one operation, saving time.

- Single-cut tap: Versatile, both manual and mechanical.

- Nut tap: Specially designed for producing internal threads in nuts.

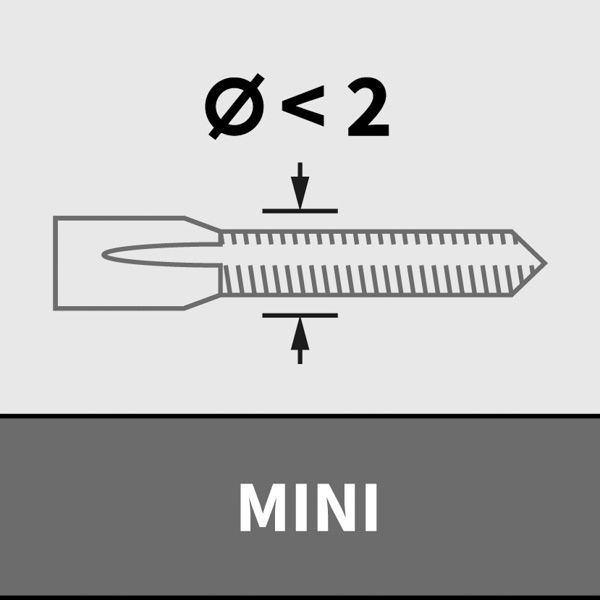

- Mini tap: For very small threads, such as those needed in model making.

- Special taps: For special requirements or unusual thread types.

To choose the right tap for your application, you should consider the following factors:

- Material: BAER offers taps for a wide range of materials from aluminum and brass to structural and stainless steels to titanium and plastics.

- Thread type and size: Choose the appropriate tap for your required thread type (e.g. metric, imperial) and size.

- Processing type: Decide between manual (hand tap) and machine processing (machine tap).

- Application environment: The UNiTap is suitable for changing requirements as it saves costs and can be used universally.

BAER offers a wide range of taps, including special models such as the UNiTap, which is known for its long service life and efficiency.

In most cases, you will actually need a regular drill (twist drill) bit to pre-drill a core hole before tapping. This ensures that the tap can work optimally. However, BAER also offers innovative solutions that combine both work steps:

Standard procedure:

- Pre-drilling with a twist drill

- Subsequent thread cutting with a tap

BAER combination machine tap:

- Drilling and thread cutting in one operation

- Saves time and reduces tool changes

- Ideal for efficient production processes

Choosing the right process depends on your specific application, the material being processed, and your efficiency requirements. The experienced BAER team will be happy to provide individual advice.

UNiTap taps from BAER are universal high-end tools that stand out from other taps with the following features:

- Material variety: Process almost all materials, including steel, stainless steel, aluminum and more.

- Special geometry: Reduces friction and torque for better cutting results.

- TiAlN coating: Increases hardness and temperature resistance for longer service life.

- Flexibility: Replaces multiple taps, allowing up to 90% cost savings.

- Efficient chip removal: Suitable for through and blind holes.

The UNiTap offers excellent thread quality and is ideal for workshops with changing requirements because a single tap can handle different cutting cases.

Yes, BAER UNiTap taps are designed for multiple uses. They are characterized by the following properties:

- Durability: Cobalt-alloyed HSSE steel and TiAlN coating ensure high resistance to friction and heat.

- Universal applicability: Suitable for almost all materials and applications.

- Long service life: Reduced friction and optimized cutting geometry extend the service life.

- Efficiency: Replace multiple tools, saving costs and streamlining workflow.

Regular inspection and care are important to ensure optimal service life.

UNiTap taps from BAER offer numerous advantages:

- Universal applicability: Suitable for almost all materials and applications.

- High precision: Create flawless threads with excellent surface quality.

- Longevity: Special TiAlN coating and HSSE material ensure long service life.

- Efficiency: Reduce tool changes and enable up to 90% cost savings.

- Easy to use: Ideal for workshops with changing requirements.

These advantages make the UNiTap a revolutionary tool in the field of thread cutting.

Dies (external thread)

Dies are used to cut or repair external threads on cylindrical components such as rods or bolts.

They serve to:

- Create new external threads to make screws or bolts

- Repair damaged or worn external threads

- To improve the accuracy of screw connections

Dies are the counterpart to taps, which are used for internal threads. Together, these tools enable the production of precise and secure screw connections in metal processing, mechanical engineering and DIY.